Our machine converts the waste materials into Syngas and steam, heat and other valuable assets.

Operating temperatures above 1000; Flameless combustion. High efficiency: about 80%.

Multiple applications for the use of thermal energy.

A Wide range of materials to be used for the process of harmful emissions into the atmosphere. Cost reduction for energy production.

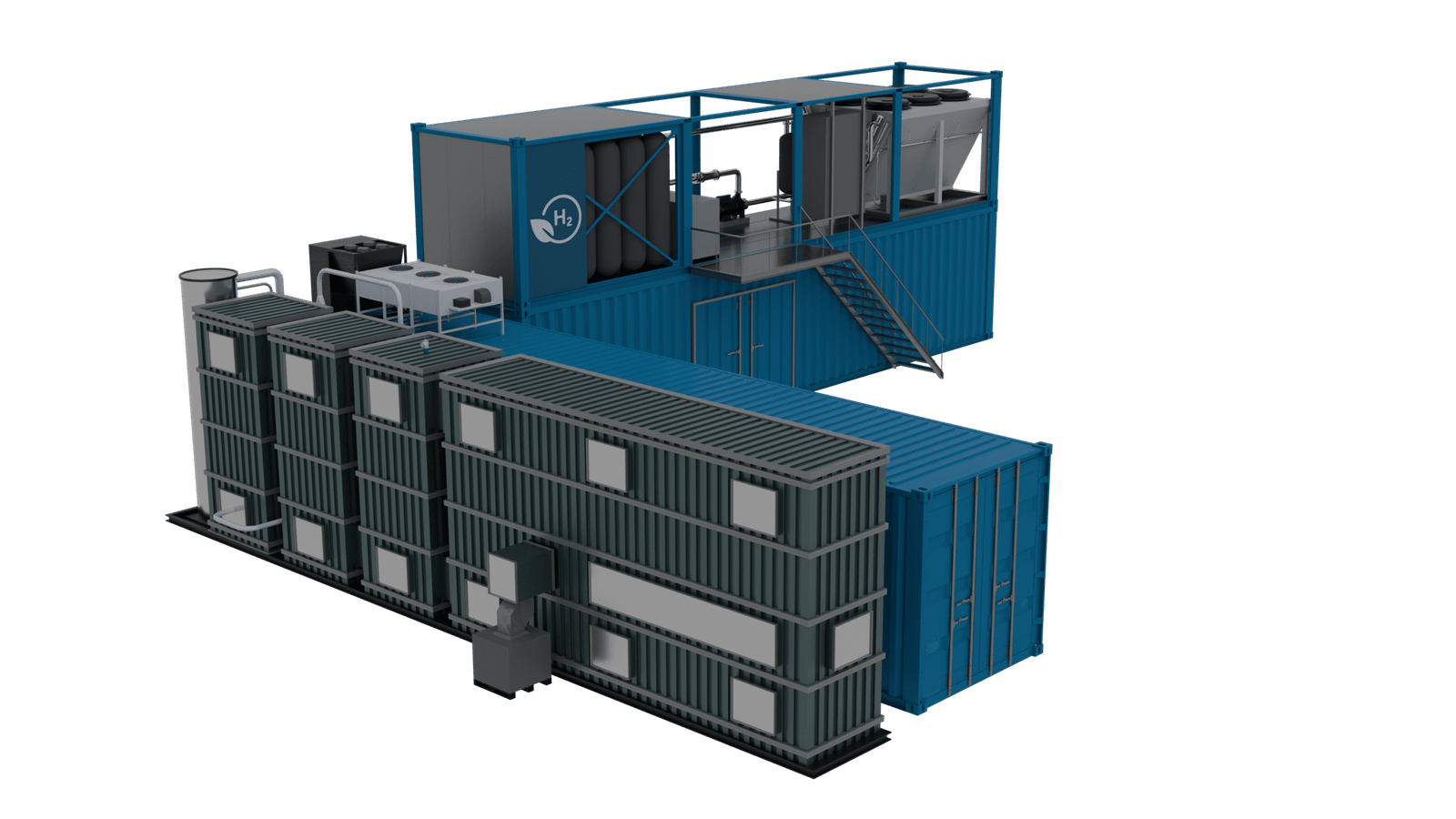

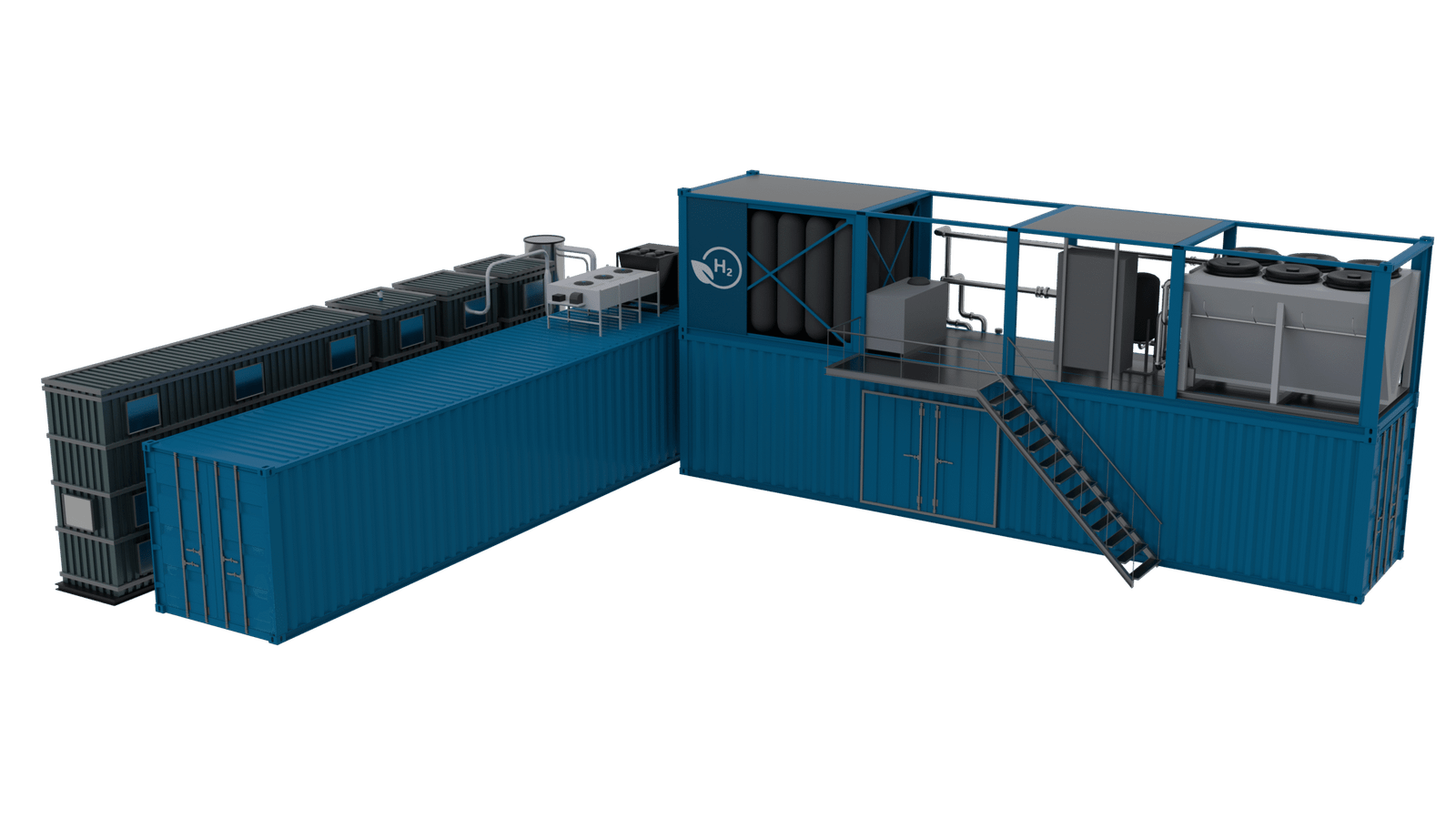

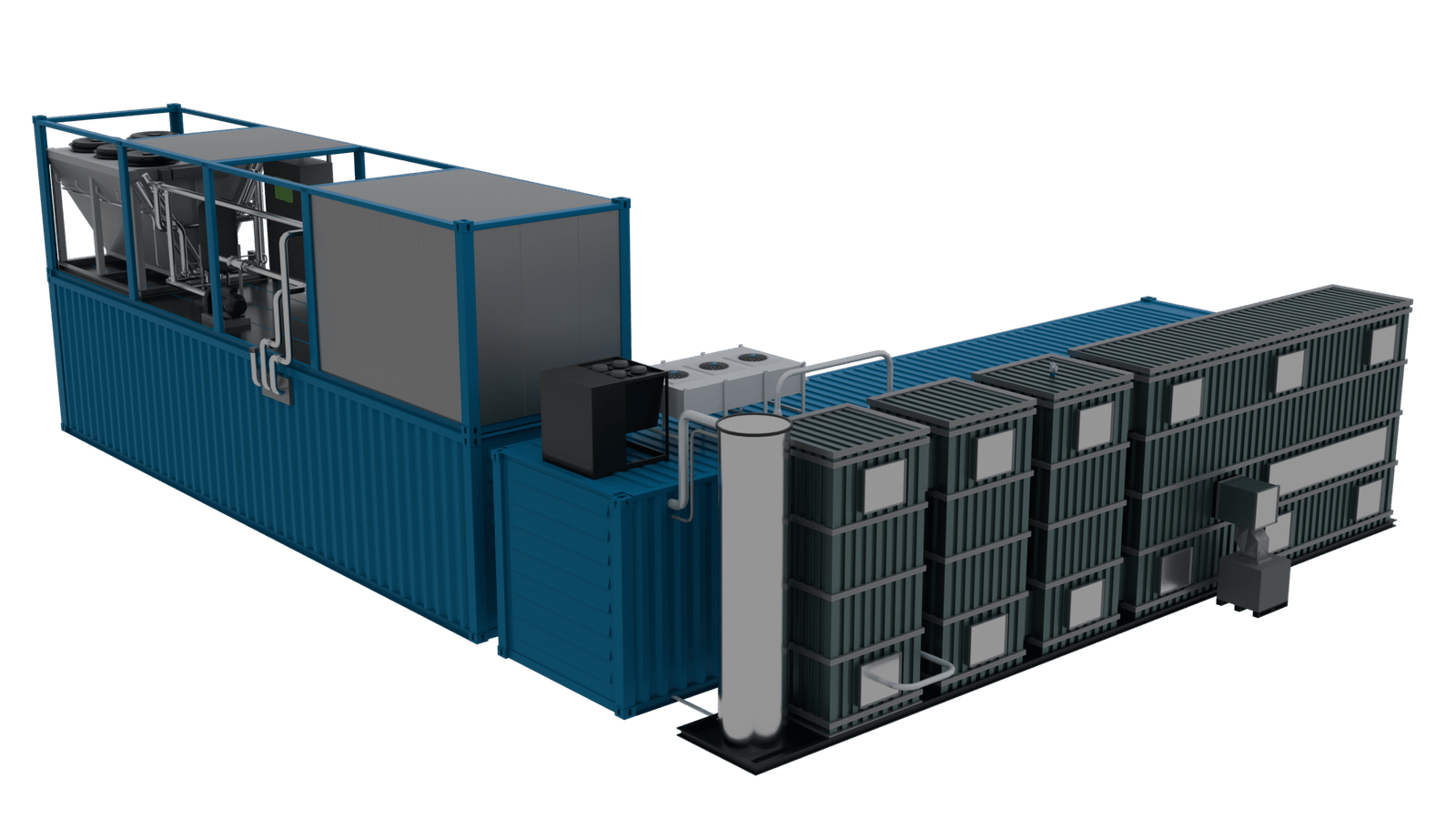

Modular (adaptable according to the available spaces).

Electricity

Thermal-Heat

Syngas

Steam/Water

CH₄

Various Fuel Sources

Rubber & Plastic

Tyres, Polyethilene, Polyurethan, Epoxy Resins

Pellet

Spruce/Fir, Common Beech

wood

Spruce/Fir, Common Beech, Oak, Poplar

Organic Waste

Leftover food, yard trimmings, fallen leaves and branches, livestock manure, untreated/unpainted wood

Nonwoven technology

Since 1987, our company has operated as a turnkey nonwoven project provider. We supply leading Spunbond & Meltblown technologies and management services, with installing and managing many nonwoven factories worldwide. Proprietary technology enables superior product flexibility making the company an industry leader.

Manufactured using state-of-the-art technologies. These technical textiles are perfect for a large number of applications and markets including the automotive, textiles, construction, and medical industries.

By integrating these technologies we have the experience and expertise to design a solution to address your company’s objective.

Whether you are upgrading existing equipment or investing in new production capacity our team will plan and deliver a project that will provide the results you expect with our 100% performance warranty.

- SPUNBOND.

- MELTBLOWN.

- NEEDLPUNCH.

- SPUNLACE.

- CONTINUOUS.

- FILAMENT.